Construction method of air conditioning system

Electromechanical systems

TMEIC 3-phase medium voltage motor

TMEIC 3-phase low voltage motor

Medium Voltage Equipment TMEIC Japan

Air conditioning system, soft and insulated duct is a very important item in most of today's civil and industrial projects,

Especially for modern construction works such as buildings, offices, commercial centers, industrial parks, factories, .., this item is indispensable.

Air conditioning system has the function of maintaining temperature, humidity, and room air is always stable, airy, and comfortable for the user while ensuring easy operation and control.

In fact, for users to easily use this system, from the stage of installation and construction of the air conditioning system, technical requirements must be met.

Construction process of air conditioning systems

1. Steps taken before actual construction

Prepare technical design drawings

For the construction of air conditioning systems correctly, correct technique, before the actual construction must proceed drawings design performance specifications.

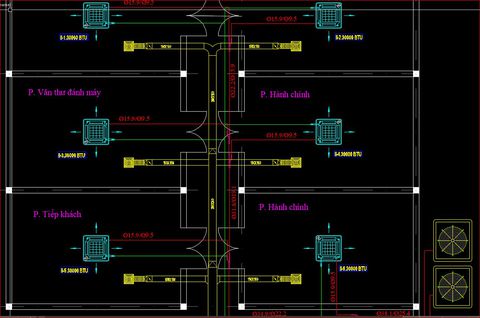

Construction technical design drawings are detailed designs representing each part of the work, show details the installation location of the actual devices so that engineers can visualize a preliminary overview of the air conditioning system is installed like in practice.

Besides that, the design drawing is also a detailed report on the specific implementation plan so that the installation engineer can communicate with the building management for the actual implementation, prepare the vehicle, warehouse for storing goods, supplies.

Mark construction area

The next stage of pre construction is the installation of temporary shielding walls, in order to isolate the construction area and the operating area of the equipment system, prepare to carry out construction of each part as planned without causing too much influence on surrounding areas.

The construction of air conditioning systems for buildings to be constructed on a rolling, finished and must comply with Vietnam standard on air conditioning TCVN 5639-1991, TCVN 5937-1995 and TCVN 5938-1995 on air quality.

Construction principles of air conditioning systems

Make sure the construction finishes by area. During the installation process needs to regularly perform industrial hygiene areas of construction. After the installation is complete, the whole system will be calibrated and tested. General cleaning of the whole project to prepare for the measurement, technology transfer and handover of acceptance.

One of the most important equipment in the central air-conditioning system is the AHU system.

2. Actual construction steps

Step 1: Tick and detailed machining

Marking is to determine exactly where the parts will be assembled, The axial positions of the pipe sections are based on the design drawings and the actual structure of the project.

The marking process includes: Determine where to run gas pipelines for air conditioning systems, location will assemble parts, axis positions of the pipe sections from here to combine with detailed construction design drawings, proceed to determine the direction, size notes of equipment, the gas pipeline, branching points, taper quail, installation positions shelving, Pylons,..

This stage is closely related to the actual design and structure drawings of the building, It should be carried out in parallel to help the equipment installation be carried out quickly without affecting the normal operation of the building.

Note: The Pylons, racks are linked to the construction structure by tools such as ciphertext, ECU, Seal ring, Ty lace, hanging belt. Pylons, shelving must be rust and paint coating before installation.

Make sure all gas piping systems, brackets, and bolt holes are pre drilled and welded.

The distance between the brackets and the brackets must comply with actual technical requirements and SMACNA standards - ventilation pipe construction standards.

Step 2: Install and run the gas pipeline, the cold air supply pipe, the fresh wind and the waste air intake

- Carry out the installation of the brackets, the brackets for the gas pipes, fittings and flexible ventilation pipes, and accessories. Use bolts - screws to attach the mounting brackets to the building structure.

- Complete line alignment of the pipes by adjusting the supports, check the tightness of gas pipes, use insulation material for reinforcement at the junction points.

- Conducting inspection and completing the entire gas pipeline system.

Step 3: Install air conditioning equipment

The installation of air-conditioning equipment (central air conditioner chiller, AHU, FCU, ..) will be conducted separately for each air conditioner unit in each area according to the design and actual work. However, the sequence conducted for units is the same.

before installation of machinery, The equipment should be thoroughly tested for its basic functions and carried out for the test operation. This is to ensure the air conditioner works well before being installed to avoid unnecessary problems later on.

Steps to be taken:

- Crane the hot trusses up to the roof and locations to install.

- Install the hot rig system at predetermined positions, premade the machine base.

- Install the cold rigs at the positions that are mounted according to the construction drawings.

- Connect the gas pipelines to the cold and hot platforms according to technical requirements.

- Conducting aligning and installing rubber mattress to create anti-vibration layer for air conditioning system.

- Perform the alignment to level the hydrostatic equipment, Tighten or loosen the bolts at the base of the appliance. This step needs to ensure the accuracy of standards <1/1000.

- Implementation of land and match play 3-phase power to the machine and determine the correct direction of rotation.

FCU is an air-handling equipment used for spaces with small areas, AHU system cannot be arranged.

Step 4: Outsourcing and installation of condenser water pipes

The steps are carried out in the following order:

- Outsourcing the rack, the rack after taking the mark.

- Carry out the installation of brackets, brackets.

- Installing PVC condenser water pipes and accessories (including collection, elbow, numb, ..).

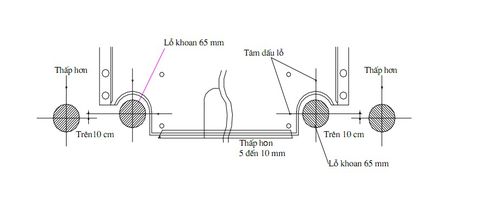

When installing PVC pipes, it is necessary to get the water level to create a minimum slope of 1/1000 for the horizontal pipe. Next, it is necessary to arrange a position to install the exhaust pipe on the ceiling with insect mesh sealing.

- Arranging siphons at the main shaft positions to drain condensate to avoid toxic vapors and polluted gases from below along the pipes entering the rooms.

- Clean the pipes for a sealed test after installation is complete, and connect the pipes to the condensate trays.

- Insert warrant the construction hole to complete this step.

Step 5: Electrical installation

The design of the total electrical cabinet consists of two main parts: the electrodynamic system for the air conditioning unit and the control system for the central control equipment. Whereby,

- The main part of the electrical cabinet will be installed, measured and tested at the workshop. The connection wires should ensure that the core is pressed, are numbered specifically and have detailed installation drawings. Coordinate with the Management Board to arrange the installation of total electrical cabinets at the most reasonable time before installing the air-conditioners.

- Conducting cable trough installation, wire trough after measuring, taking the mark is complete.

- Next is to conduct the power cable from the cabinet to the air conditioner.

- Check all electrodynamics and control power

- Acceptance of techniques, complete the line before connecting to the general electrical cabinet and the air conditioner or controller.

Attention:

- All protective devices need to be fully assembled and synchronized in the air conditioner. The program control system will be implemented by the Intelligent Controller central controller.

- All connection points must be securely connected by a fighting bridge and numbered terminals must be used.

After the inspection is completed the entire line will be connected to the power supply to the automat.

The next step after the installation is completed, the following steps should be performed:

- Check the air ducts, the water pipes and the respective equipment.

- Implementation of the guidelines specified by the device manufacturer.

- Electrodynamic connector to conduct test run, check and adjust parameters related to each part of the air conditioning unit:

+ Check the air conditioning supply voltage parameters.

+ Test running cold load blower of air conditioner, Check that the current of the fan motors are correct for the equipment manufacturer's rating.

+ Check the entire soft duct system with insulation again, electrodynamic system, .. in a state of operational readiness equipment.

- Next is the process of running the compressor:

+ Start the compressor

+ Check the parameters of voltage, current, pressure, ..

+Check the parameters in the air-conditioned room about: Temperature and wind speed at the mouth and surrounding areas.

Note: The execution of the above checks must be supervised by the responsible engineer and recorded in minutes.

Step 6: Connect the central control system

After all the air conditioning units have been installed and put into operation, the connection to the central control cabinet for the whole air-conditioning system will be made.

Implementation steps:

- Connect each device to the central control cabinet.

- Test run connect each device.

- Calibrate the whole system and run the test according to the modes designed on the basis of the requirements of the investor.

Above are the stages in the construction of standard air conditioning systems. For the air conditioning system to work effectively, right from the selection of materials, equipment, accessories,.. should be the most tightly controlled.

Tan Hoang Phat is a supplier of insulation materials for the construction of ventilation systems, construction of air-conditioning systems such as soft ducts, insulated glass wool, ... High quality with reasonable price.

In addition, Tan Hoang Phat is also a supplier of metal materials, construction accessories with prestige and long-term experience in the market. Steel pipe products, wire rods, threaded rods, bolts - washers, formwork accessories - scaffolding, .. are always highly appreciated by customers.

DIENCONGNGHIEP.TOP

Quality pioneer

Skilled technical team, professional

Cost savings

Rapid construction

Labor safety assurance

Provide 100% genuine products

Design and design verification

- Factory design

- Industrial buildings,

- Design ventilation air conditioning system,

- Mild electrical design,

- Heavy electrical design,

- Fire protection design.

- Water supply and drainage design.

Construction

- Construction of light electrical systems

- Construction of fire protection system.

- Factory design and construction

- Design and Construction of electromechanical works

- Electrical construction

- Construction of the factory electromechanical system

- Construction of M&E system

- Installation of electromechanical systems

- Construction of air conditioning system

- Construction of ventilation system

- Installation of HVAC system

- Install cold cellar cold room

- Design and installation of clean rooms

- Construction of clean rooms

- Factory design

- Apply for a factory building permit

- Fastest factory building design

- Construction of water supply and drainage system

- Construction of camera system

- Construction of water supply and drainage system

Product distribution

- Genuine distribution

- Quality assurance

- Full CO CQ

- Long-term warranty works

CONTACT OFFICE

Tan Hoang Phat Design and Construction Investment Company Limited

Address: 5th Floor, Central Point 219 Trung Kinh, Yen Hoa Cau Giay, Hanoi City

Website: http://diencongnghiep.top

Email: diencongnghiep.top@gmail.com

Facebook: https://www.facebook.com/congtytanhoangphat

Hotline: 0911.066.518, 0969.002.382