Clean room construction

Electromechanical systems

TMEIC 3-phase medium voltage motor

TMEIC 3-phase low voltage motor

Medium Voltage Equipment TMEIC Japan

Nowadays, the use of clean spaces for production, packing, Experiment and research have become an indispensable part of the industry. Tan Hoang Phat Design and Construction Investment Co., Ltd is a company with extensive experience in clean room project chains. We specialize in providing clean room equipment systems with flat surfaces, cleanable is very suitable for the medicine industries, biotechnology, electronics and food processing industries, cosmetic…

Please introduce the consulting work of designing and installing clean rooms, clean room construction from the time the customer orders to the completion of the warranty, maintenance:

Clean room concept

What is clean room construction?

According to the specialized definition, A clean room is a room in which the concentration of particles suspended in the air and other factors such as temperature, humidity and pressure are controlled and controlled to provide an extremely sophisticated working system and modern.

In a way that is easy to understand, the simplest, clean room is a closed room, in which the amount of dust is minimized; temperature, pressure and humidity are controlled and controlled to keep research, manufacturing and production from being dirty, no harmful gas, guaranteed sterility, "Clean" as what it means.

Clean room applications in pharmaceutical production

Some common applications of clean room construction

Nowadays, clean rooms are increasingly popular and widely used in the research and development industries, medicine and industry. Depending on the requirements and complexity of the working environment clean rooms can be applied in that field. Currently clean rooms are applied in a number of industries such as:

- Clean room for agricultural research and development, biological.

- Clean room used in research and development of new products, high-tech products.

- Clean rooms to support the health sector: surgery, Special patient care also known as isolation rooms, sterile room.

- Clean rooms used for the manufacture of medicines, medical equipment. Post production pharmaceutical storage to increase time and maintain quality.

- Food preservation, special goods, special additives and materials ...

- The cleanroom serves research, manufacture of electronic circuits, semiconductor electronics.

Clean room applications in electronics manufacturing

Clean room installation design standards

The cleanroom design and installation standard is a synthesis of technical requirements and specifications issued by the Ministry of Health, temperature, pressure and control the amount of bacteria as desired. This is the easiest concept to understand and imagine for the question of what is the standard of clean room installation?

Up to now the design standards of clean room installation are still the concentration of dust particles suspended in the air and dust controlled by a certain standard.

Below are some recognized standards for clean room design and construction. Here are some standards that have been recognized in the design and clean room construction.

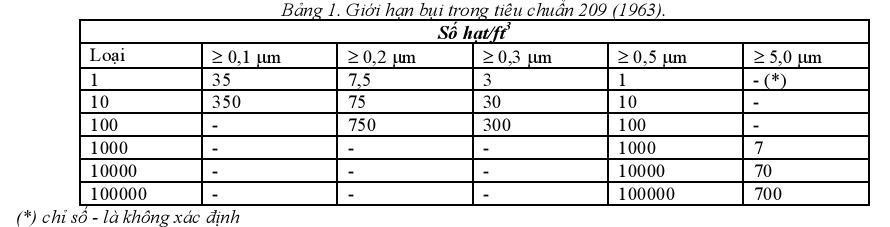

Clean room construction standards Federal Standard 209 (1963)

This standard was first specified in 1963 (named 209), and then continually improving, completing versions 209 A (1966), 290 B (1973)…, up to 209 E (1992).

Federal Standard 209 clean room standards

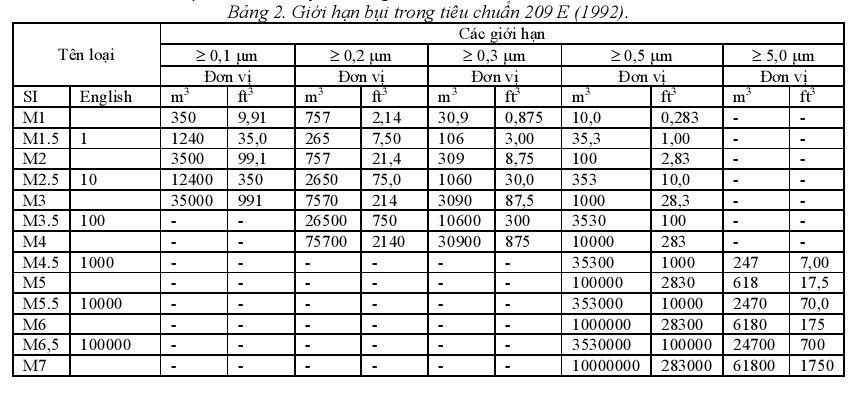

Clean room construction standards Federal Standard Federal Standard 209 E (1992)

This standard defines the concentration of dust in the air according to the standard unit (the unit of air volume is cubic meter). The clean room classification is determined by the dust content according to the particle diameter. Below is a standard table of FS 209 E.

Federal Standard 209 E clean room standards

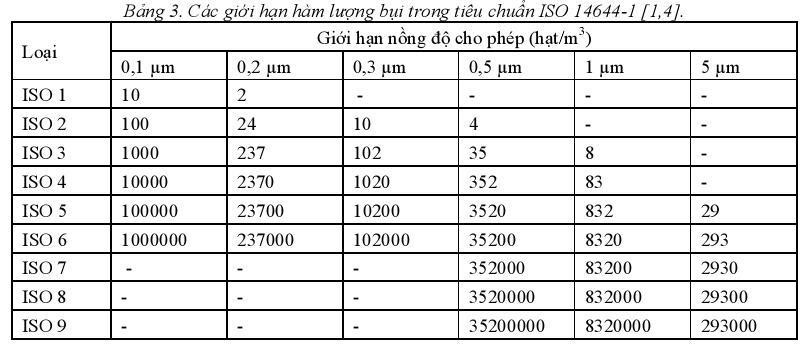

Clean room construction standards ISO 14644-1

International Standards Organization (ISO) has defined standards for clean rooms of international standard. ISO 14644-1 was released in 1999 called "Classification of air cleanliness" with specific content as follows:

Clean room standard ISO 14644-1

Clean room construction classification (Cleanroom class)

in practice depending on the requirements of use and the purpose of use, technical requirements with which all kinds of clean room clean room will be used. Here are some cleanroom classifications and applications that apply to a number of popular industries:

Clean Room Type | Clean room type in english | Application |

Type 1 | (Cleanroom Class 1) | - Applicable to clean rooms belonging to integrated circuit factories with Super small size technology. |

Type 10 | (Cleanroom Class 10) | - Applicable to room type of semiconductor factories used to manufacture integrated circuits with width less than 2 ILm. |

Type 100 | (Cleanroom Class 100) | - Clean room type requires no bacteria, dust for use in the manufacture of sterile injectable drugs. - Clean room type tissue transplant surgery. - Type of clean room postoperative after bone tissue transplant surgery. |

Type 1,000 | (Cleanroom Class 1,000) | - Type of production room for high quality optical equipment. - Type of room for the production of micro bearings. |

Type 10,000 | (Cleanroom Class 10,000) | - Type of hydraulic equipment assembly room, Pneumatic, servo control valves, high quality timers and actuators. - Room type used to manufacture sterile injectable drugs. |

Type 100,000 | (Cleanroom Class 100,000) | - Room type used for work related to optics. - Type of room used for assembly of electronic components, hydraulic and pneumatic. - clean room type used for pharmaceutical production, foodstuffs. |

Clean room design process

Receive the request and conduct the survey clean room construction

Upon receiving a request from a customer, Tan Hoang Phat will send clean room experts from the company to talk directly with guests to survey, measure the parameters at the location to be installed according to the customers requirements and our expertise to come up with the most appropriate preliminary plan.

Conduct drawing design clean room construction

Based on requirements from customers, measured parameters such as structure, area, pressure, degree of air circulation, ... We will redesign into the most complete technical drawing of clean room system from structure, installation equipment, ... meet the requirements of the project and the customer.

Conduct clean room construction

The above clean room installation blueprint will be agreed with the customer, the weight calculation will then proceed, quote and agree on the plan and installation process, clean room construction for the project.

The steps to install, the equipment used, the materials, are in strict accordance with the strict standards in the clean room. Monitoring will be carried out simultaneously by both parties due to the techniques, Our leading specialist to ensure the degree of tightness, Pressure, Standard amount of dust in the rooms meet the requirements as agreed earlier.

Clean room construction completed

Conduct acceptance for the clean room construction and put into use

Clean room construction warranty

Perform warranty, maintenance works according to the initial commitment to customers.

CONTACT OFFICE

Tan Hoang Phat Design and Construction Investment Company Limited

Address: 5th Floor, Central Point 219 Trung Kinh, Yen Hoa Cau Giay, Hanoi City

Website: http://diencongnghiep.top

Email: diencongnghiep.top@gmail.com

Facebook: https://www.facebook.com/congtytanhoangphat

Hotline: 0911.066.518, 0969.002.382